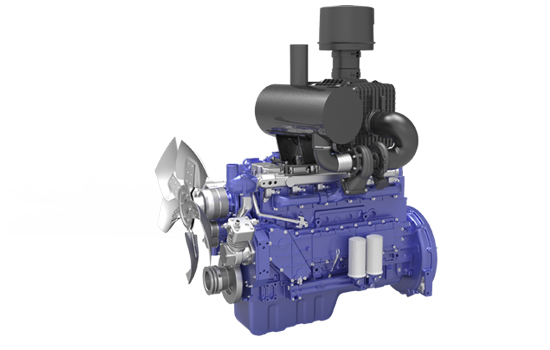

WP10 series engine for construction machinery

Product portfolio

| Model |

Displacement

(L) |

Number of valves per cylinde |

Rated power/speed

(kW/rpm) |

Maximum torque/speed

(N.m/rpm) |

Technical route |

Applicable model |

| WP10G210E341 |

9.7 |

4

|

154/2200 |

950/1400-1600 |

CR |

Loaders |

| WP10G210E342 |

9.7 |

4

|

154/2100 |

950/1200-1400 |

CR |

Loaders |

| WP10G210E343 |

9.7 |

4

|

154/2000 |

980/1300-1500 |

CR |

Loaders |

| WP10G210E344 |

9.7 |

4

|

154/1900 |

980/1300-1500 |

CR |

Loaders |

| WP10G220E341 |

9.7 |

4 |

162/2200 |

950/1400-1600 |

CR |

Loaders, forklifts, rollers |

| WP10G220E342 |

9.7 |

4 |

162/2100 |

950/1200-1400 |

CR |

Loaders |

| WP10G220E343 |

9.7 |

4 |

162/2000 |

980/1300-1500 |

CR |

Loaders |

| WP10G231E343 |

9.7 |

4 |

170/2000 |

1150/1200-1500 |

CR |

Loaders |

| WP10G240E341 |

9.7 |

4 |

178/2200 |

1100/1400-1600 |

CR |

Loaders, rollers |

| WP10G240E343 |

9.7 |

4 |

178/2000 |

1100/1300-1500 |

CR |

Loaders |

| WP10G240E342 |

9.7 |

4

|

178/2100 |

1100/1300-1500 |

CR |

Loaders |

| WP10G270E341 |

9.7 |

4 |

199/2200 |

1100/1400-1600 |

CR |

Loaders, rollers |

| WP10G286E301 |

9.7 |

4 |

210/2200 |

1185/1600-1800 |

CR |

Loaders |

| WP10.310E53 |

9.7 |

4 |

228/1900 |

1500/1200-1500 |

CR+SCR |

36T truck cranes |

| WP10.336E53 |

9.7 |

4 |

247/1900 |

1550/1200-1500 |

CR+SCR |

55T truck cranes |

| WP10.375E53 |

9.7 |

4 |

276/1900 |

1650/1200-1600 |

CR+SCR |

75T truck cranes |

| WP10G336E344 |

9.7 |

4 |

247/1900 |

1550/1100-1400 |

CR |

Crawler cranes |

Product advantages

Powerful, better economy

Output torque at low speed is increased by 13%, improving the acceleration performance of the engine.

The high torque is increased by 9%, improving the power performance further.

The four-valve structure guarantees the high intake efficiency, full combustion, and good economy

Quiet, reliable and more comfortable

GDI is adopted, which improves the combustion state and efficiency, and thus effectively reduces fuel consumption and vibration, noise of the engine.

The hyperboloidal plastic fan is adopted, which improves the thermal dissipation efficiency and reduces the radiation noise level of the engine effectively, making driving more comfortable and secure.

The high frequency torsional vibration zone of the engine is avoided, reducing engine noise by 2dB.

The movement speed of moving parts is reduced, the movement time is prolonged, the wear of friction pairs per unit time is reduced, and the service life of the crankshaft flywheel system and gear system is prolonged.

B10 life is greater than 30,000h.

Easy maintena.nce and wide range of application

Weichai's patented "93% dust filter" is used, such that the first-level coarse filtration efficiency is as high as 93%, reducing the early wear rate of the four accessories of engine by more than 90%.

The three-level fuel filter ensures good fuel adaptability and improves reliability.

The remote signal transmission of oil filter is used, improving the convenience of maintenance and saving both time and effort.

500h oil change period is ensured, reducing the usage cost.

Reliable

High reliability design guarantees the service life of 30,000h.

Environmental adaptability

Temperature -35℃~50℃ ,altitude below 4000m.

Back to top