400-618-3066

- Home

-

Our group

-

Group profile

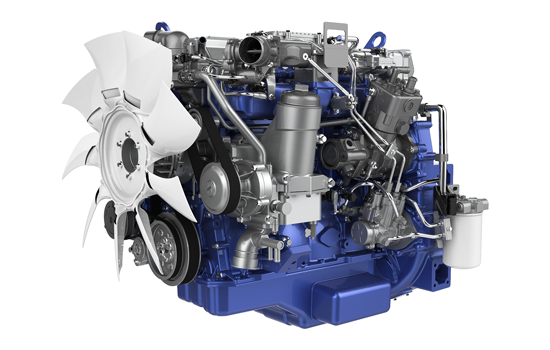

Weichai is a multi-field and multi-industry international group which owns powertrain systems, commercial vehicles, agricultural equipment, construction machinery, intelligent logistics, marine mobility, and energy & power solutions.

Member of WeichaiWeichai is a multi-field and multi-industry international group.

Corporate cultureWe aim at customers' satisfaction

Compliance and IntegrityCompliance increases credit,Legal affairs bring honesty

Business SchoolOpenness, Innovation, Sharing and Win-win

-

-

Products & Service

-

Our brands

Our Business

Luxury yacht

-

-

Human resources

-

Recruitment information

Possess both integrity and ability and put integrity the very first. Attract talent worldwide and nurture talent from inside.

Training & DevelopmentWeichai Group had rich training resources, and has established a professional training team with a number of high-quality trainers

Welfare benefitsThe company provides competitive salary, include five insurances and housing fund.

-

-

Media center

-

Group news

Get to know the latest Group news and information

Picture libraryDisplay the historical moment of Weichai with pictures

Video libraryRecord the development track of Weichai with videos

-