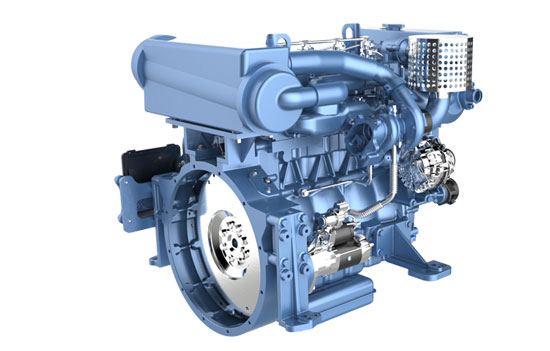

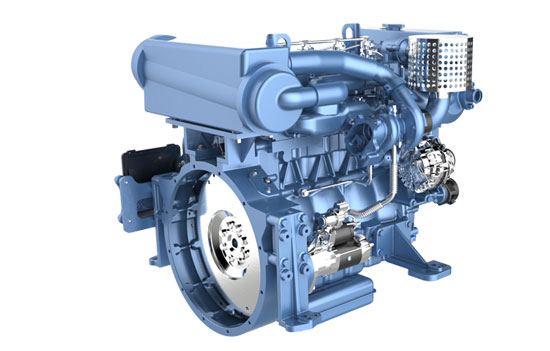

Weichai WP3N series marine diesel engine (85-118kW)

Parameters Table

| Type |

Four-stroke, water cooled, in-line, turbocharged and aftercooled |

Number of cylinders |

4 |

| Bore & stroke |

94×107 (mm) |

Displacement |

2.97L |

| Oil consumption rate |

≤0.1 g/kW·h |

Noise |

≤98 dB(A) |

| Minimum fuel consumption rate |

198 g/kW·h |

Idle speed |

750 r/min |

Rotation

(facing the flywheel) |

Counter-clockwise |

Net weight |

337 kg |

| Dimensions (L×W×H) |

830×690×780 (mm) |

Model Portfolio Table

| Series |

Model |

Air intake mode |

Rated power kW/Ps |

Speed r/minn |

Fuel feeding mode |

Emission level |

Power classification |

| WP3N* |

WP3NC115-30E220 |

Turbocharged and intercooled |

85/115 |

3000 |

HPCR |

- |

P3 |

| WP3NC130-30E220 |

Turbocharged and intercooled |

95/130 |

3000 |

HPCR |

- |

P3 |

| WP3NC150-30E220 |

Turbocharged and intercooled |

110/150 |

3000 |

HPCR |

- |

P3 |

| WP3NC160-30E220 |

Turbocharged and intercooled |

118/160 |

3000 |

HPCR |

- |

P3 |

Remark: Product parameters and model portfolio are for reference only. Please contact relevant personnel for official information on delivery time and fishing boat model portfolio.

Product description

Safe and reliable

- The high-strength design of structural parts such as the body, piston, and bearing bush ensures the reliability of the diesel engine under high explosion pressure

- The supercharger, starter, fuel system and other important parts adopt global excellent suppliers

- Withstand the most demanding and rigorous benches, and have passed the tests of plateau, high temperature and high cold to ensure the reliability of key components, and the overhaul period of the whole machine is more than 12000h

- Perfect self-diagnosis system, perfect failure protection mode and safe control strategy

Strong power

- The key components are developed by Weichai's high-quality suppliers and developed in accordance with the high reliability requirements of the marine machinery industry

- Low-speed and high-torque design, large torque reserve, rapid response and fast speed increase

Economical and fuel-efficient

- Optimize fuel injection rules, accurately control fuel injection pressure, fuel injection volume and fuel injection time, fully atomize fuel, wide economic fuel consumption range, and minimum fuel consumption rate of 198g/kW•h

- Customized design for lower fuel consumption

Comfortable and environmentally friendly

- The rear gear room and enclosed flywheel housing can effectively reduce noise. The standard noise is 4dB(A) lower than competing products, and the no-load noise is 2.5 dB(A)-4 dB(A) lower than competing products

- Adopt body reinforcement plate and piston pin offset structure, the vibration of the whole machine is better than the competition products

- IMO II emission requirements are met

Strong applicability

- Special LCD Internet instrument, vibration isolation pad, water jacket exhaust pipe and other optional configuration

- More than 95% parts and N series products are common, easy to maintain

- Adjust different control strategies according to different performance requirements

- Accept or output a variety of control signals to meet the needs of automation control