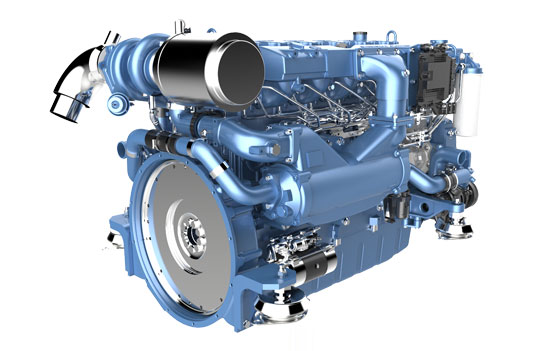

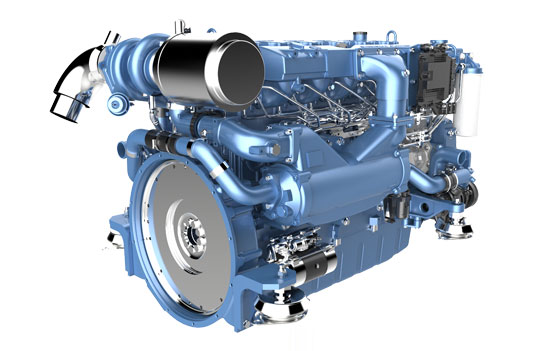

Weichai WP10 series marine diesel engine (230-290kW)

Parameters Table

| Type |

Four-stroke, water cooled, in-line, turbocharged and aftercooled |

Number of cylinders |

6 |

| Bore & stroke |

126×130 (mm) |

Displacement |

9.726 L |

| Oil consumption rate |

≤0.5 g/kW.h |

Noise |

≤97 dB(A) |

| Minimum fuel consumption rate |

191 g/kW.h |

Idle speed |

600±50 r/min |

| Torque reserve |

20-35% |

Net weight |

1070 kg |

Rotation

(facing the flywheel) |

Counter-clockwise |

Emission |

IMO II |

| Dimensions (L×W×H) |

1482×981×1016 (mm) |

Model Portfolio Table

| Series |

Model |

Aspiration |

Rated power

kW/Ps |

Speed

r/min |

Fuel system |

Emission |

Power rating |

| WP10 |

WP10C313-21 |

TA |

230/313 |

2130 |

HPCR |

IMO Ⅱ |

P1 |

| WP10C350-18 |

TA |

257/350 |

1800 |

HPCR |

IMO Ⅱ |

P1 |

| WP10C375-21 |

TA |

275/375 |

2100 |

HPCR |

IMO Ⅱ |

P2 |

| WP10C395-22 |

TA |

290/395 |

2200 |

HPCR |

IMO Ⅱ |

P3 |

Remark: Product parameters and model portfolio are for reference only. Please contact relevant personnel for official information on delivery time and fishing boat model portfolio.

Product description

Safe and reliable

- The high-strength design of structural parts such as engine block, piston and bearing bush ensures the reliability of diesel engine under high explosion pressure

- For turbocharger, starter, high-pressure oil pump and other important parts, global excellent suppliers are used

- Withstand the most stringent durability test and assessment; ensure the reliability of key parts and components; and the overhaul period of the whole engine is over 20000h

- Perfect self-diagnosis system, perfect failure protection mode, and safe control strategy

Strong power

- Accurate control by electronic control units, high injection pressure, small fluctuation of rotating speed, and strong power

- Low-speed and high-torque design with the torque reserve of 20%-35%, quick response, and fast speed increase

Economical and fuel-efficient

- The fuel injection law is optimized, the fuel injection pressure, fuel injection quantity and fuel injection time are accurately controlled, the fuel is fully atomized, and the minimum fuel consumption rate is 191g/kW•h

- Customized design for lower fuel consumption

Comfortable and environmentally friendly

- It can realize multiple injections such as pre-injection and post-injection, and the noise and vibration are reduced by 20% compared with the mechanical pump system

- Water jacket exhaust pipe and water jacket exhaust tail pipe are used to reduce engine compartment temperature

- IMOⅡ ship emission standards are met

Strong practicability

- LCD Internet instruments, vibration isolators, and hand-pressed oil well pumps can be equipped to meet the requirements of different customers

- Horizontal air filter and rear turbocharger reduce the height of the whole engine and facilitate the layout of the engine compartment

- Different control strategies are adjusted according to different performance requirements

- Receive/output various control signals, which meet the requirements of automation control