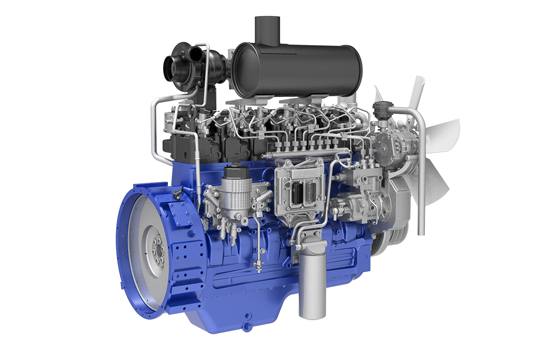

WP6 series engine for agricultural machinery

Product portfolio

| Mode |

Displacement

(L) |

Number of valves per cylinder |

Rated power/speed

(kW/rpm) |

Maximum torque/speed

(N.m/rpm) |

Technical route |

Applicable model |

| WP6G150E310A |

6.75

|

2 |

111/2200 |

600/1400-1600 |

Common rail + turbocharged and inter-cooled |

130Ps tractor |

| WP6G160E311 |

6.75

|

2 |

118/2200 |

665/1500-1700 |

Common rail + turbocharged and inter-cooled |

140Ps /150Ps tractor |

| WP6G160E330 |

6.75

|

2 |

118/2200 |

665/1400-1700 |

Common rail + turbocharged and inter-cooled |

corn harvester |

| WP6G175E331 |

6.75

|

2 |

129/2200 |

750/1400-1700 |

Common rail + turbocharged and inter-cooled |

corn harvester |

| WP6G180E330 |

6.75

|

2 |

132.5/2200 |

750/1400-1700 |

Common rail + turbocharged and inter-cooled |

corn harvester |

| WP6G180E330A |

6.75

|

2 |

132.5/2200 |

753/1400-1700 |

Common rail + turbocharged and inter-cooled |

160Ps tractor |

| WP6G190E330 |

6.75

|

2 |

140/2200 |

760/1400-1600 |

Common rail + turbocharged and inter-cooled |

corn harvester |

| WP6G200E330 |

6.75

|

2 |

147/2200 |

860/1400-1600 |

Common rail + turbocharged and inter-cooled |

corn harvester,180Ps tractor |

| WP6G210E330 |

6.75

|

2 |

154/2200 |

860/1400-1700 |

Common rail + turbocharged and inter-cooled |

corn harvester |

| WP6G210E311 |

6.75

|

2 |

154/2200 |

860/1400-1600 |

Common rail + turbocharged and inter-cooled |

200Ps tractor |

| WP6G220E330A |

6.75

|

2 |

162/2200 |

860/1400-1600 |

Common rail + turbocharged and inter-cooled |

corn harvester |

| WP6G220E330 |

6.75 |

2 |

162/2200 |

860/1400-1600 |

Common rail + turbocharged and inter-cooled |

210Ps tractor |

Product advantages

More reliable — high configuration and low failure rate

Parts from famous and premium domestic and foreign suppliers are used, improving reliability and reducing failure rate effectively.

The BOSCH electronically controlled high-pressure common rail system ensures a higher reliability.

The 93% dust filter can be used in dusty environments with various soil properties, prolonging the maintenance period of main filter element and reducing the operating cost.

The crankshaft made of forged steel guarantees a higher strength and the power of front PTO may be as high as 45kW.

The three-level filter completely removes the water and impurities from the fuel, reducing the failure rate of the fuel system significantly.

Automatic tensioning makes the engine run more stably, improving pump reliability and reducing vibration noise effectively.

The electric system supplier is selected, reducing the failure rate of electric system effectively.

The poly V-belt ensures a high transmission efficiency, low belt transmission noise, and prolonged belt replacement period.

More efficient — powerful and efficient

Constant power at high speed, constant torque at low speed, and good acceleration performance.

The torque reserve rate is higher than 30%, which meets the soil and agronomic requirements in different regions better, ensuing high operation efficiency.

Better economy — accurate fuel control and low fuel consumption

The turbocharger, fuel injector and calibration data of ECU are optimized, and multiple injections are realized by controlling fuel injection pressure flexibly, such that fuel consumption is reduced and work efficiency is improved.

More comfortable — low vibration and noise

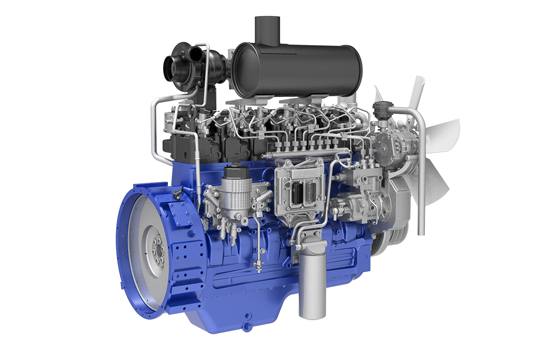

Phased management, which can be used to locate the agricultural machinery purchased on installment and send a payment reminder.

Fuel consumption management, which can be used to record, monitor and store the real-time fuel consumption and combined fuel consumption of the engine in real time.

Speed management, which can be used to record, monitor and store the real-time vehicle speed in real time.

Positioning management, which can used to locate the agricultural machinery accurately.

Anti-theft, which can be used to track and locate the stolen agricultural machinery, and lock it remotely.

Abnormality reminder, which can be used to monitor the operating parameters of the engine in real time and give early warning of hidden dangers and faults.

Remote diagnosis, which can be used to give an alarm automatically in case any fault is found and analyze the engine fault remotely.

More intelligent — real-time monitoring and remote control

The engine adapts to high temperature or dusty environments with various soil properties.

The engine can start normally at -15°C without auxiliary measures, indicating a good low temperature start ability.

Better adaptability — cope with the challenges from complex environments flexibly.

The engine can start normally at -15°C without auxiliary measures, indicating a good low temperature start ability.

The engine adapts to high temperature or dusty environments with various soil properties.

Drain interval

500h oil drain interval.

Environmental adaptability

Temperature -35℃~50℃ ,altitude below 4000m.