400-618-3066

- Home

-

Our group

-

Chairman

CV of Mr. Tan Xuguang

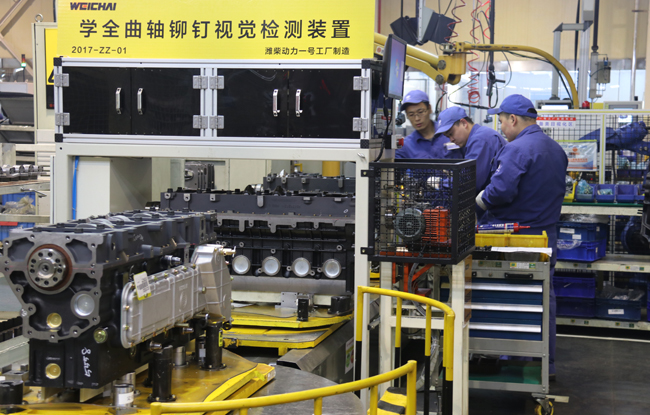

Group profileFounded in 1946, Weichai has over 100,000 employees worldwide. The Group has 11 stocks from 8 companies listed at home and abroad, a global workforce of 100,000 and an annual revenue of more than 300 billion yuan. It ranks 86th in China's Top 500 Enterprises, 31st in China's Top 500 Manufacturing Industry Enterprises, and 18th in China's top 100 Multinational Companies.

Member of WeichaiWeichai is a multi-field and multi-industry international group.

Corporate cultureResponsibility, Communication, Diversity

Compliance and IntegrityCompliance increases credit,Legal affairs bring honesty

-

-

Products & Service

-

Our brands

Our Business

Luxury yacht

Online service

-

-

Human resources

-

Recruitment information

Possess both integrity and ability and put integrity the very first. Attract talent worldwide and nurture talent from inside.

Training & DevelopmentWeichai Group had rich training resources, and has established a professional training team with a number of high-quality trainers

Welfare benefitsThe company provides competitive salary, include five insurances and housing fund.

-

-

Media center

-

Group news

Get to know the latest Group news and information

Picture libraryDisplay the historical moment of Weichai with pictures

Video libraryRecord the development track of Weichai with videos

-