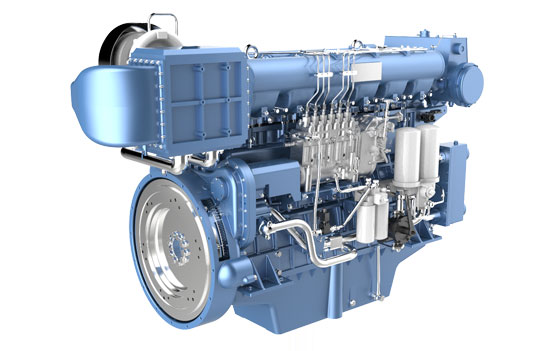

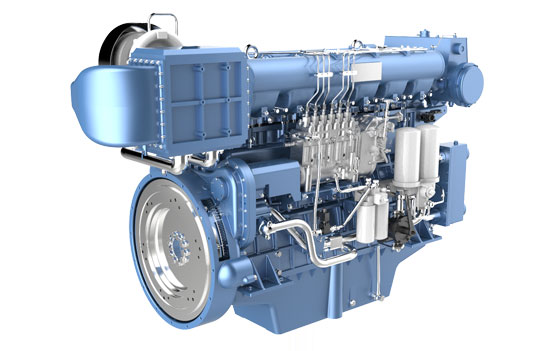

Weichai 170 series marine diesel engine (258-735kW)

Parameters Table

| Type |

Four-stroke, water cooled, in-line, turbocharged and aftercooled |

Number of cylinders |

6 / 8 |

| Bore & stroke |

170×200 (mm) |

Displacement |

27.24 L / 36.32 L |

| Oil consumption rate |

≤0.5 g/kW.h |

Noise |

≤105 dB(A) |

| Minimum fuel consumption rate |

197 g/kW.h |

Idle speed |

450-650 r/min |

| Torque reserve |

20-34% |

Rotation

(facing the flywheel) |

Counter-clockwise |

| Dimensions L×W×H) / net weight |

L6 2463×1200×1650 (mm) / 3100kg

L8 2650×1040×1818 (mm) / 3800kg |

Model Portfolio Table

| Series |

Model |

Aspiration |

Rated power kW/Ps |

Speed

r/min |

Fuel system |

Emission |

Power rating |

| X6170 |

X6170ZC350-1 |

TA |

258/350 |

1000 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC408-1 |

TA |

300/408 |

1000 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC450-1 |

TA |

330/450 |

1000 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC480-2 |

TA |

353/480 |

1200 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC540-2 |

TA |

397/540 |

1200 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC620-2 |

TA |

456/620 |

1200 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC650-2 |

TA |

478/650 |

1200 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC580-3 |

TA |

426/580 |

1350 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC680-3 |

TA |

500/680 |

1350 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC620-5 |

TA |

456/620 |

1500 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC550-5 |

TA |

404/550 |

1500 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC756-5 |

TA |

556/756 |

1500 |

Mechanical pump |

IMO Ⅱ |

P1 |

| X6170ZC818-5 |

TA |

601/818 |

1500 |

Mechanical pump |

IMO Ⅱ |

P1 |

| 8170 |

8170ZC600-1 |

TA |

441/600 |

1000 |

Mechanical pump |

IMO Ⅱ |

P1 |

| 8170ZC720-2 |

TA |

530/720 |

1200 |

Mechanical pump |

IMO Ⅱ |

P1 |

| 8170ZC818-3 |

TA |

601/818 |

1350 |

Mechanical pump |

IMO Ⅱ |

P1 |

| 8170ZC900-3 |

TA |

661/900 |

1350 |

Mechanical pump |

IMO Ⅱ |

P1 |

| 8170ZC900-5 |

TA |

661/900 |

15000 |

Mechanical pump |

IMO Ⅱ |

P1 |

| 8170ZC1000-5 |

TA |

735/1000 |

1500 |

Mechanical pump |

IMO Ⅱ |

P1 |

Remark: Product parameters and model portfolio are for reference only. Please contact relevant personnel for official information on delivery time and fishing boat model portfolio.

Product description

Safe and reliable

- High strength engine block, crankshaft and connecting rod ensure that the overhaul period of diesel engine is not less than 20000h

- The high-flow lubrication system with filtering before cooling and the high-efficiency cooling system are modularized and designed with one block and one head, which ensure the reliability of diesel engine parts and the convenience of use and maintenance

- Replace the filter without stopping

Strong power

- The shapes of high-pressure oil pump, turbocharger, injector, air valve and combustion chamber are reasonably and optimally matched, with wide power coverage and large torque reserve (more than 30%), which makes its power performance index rank at a leading position among similar products

Economical and fuel-efficient

- The engines are featured by four-valve technology, pulse conversion turbocharger, large intake air volume, sufficient combustion, wide economic operation range, and the lowest fuel consumption rate can reach 197g/kW•h

- Customized design for lower fuel consumption

Comfortable and environmentally friendly

- The design of key components is strengthened, so that the vibration index of the products reaches Grade A of the 11 grades, and the noise index is 5dB lower than that of similar products, reaching the leading level of the world

Strong practicability

- The unique Yuanhangbao monitoring system can monitor the speed, water temperature, oil temperature, oil pressure and other parameters of a diesel engine in real time. When the parameters of the diesel engine exceed the limit, it can automatically alarm and stop the engine, and the addition of stormy wave mode ensures that the ship engine will not stop at critical moments such as stormy wave